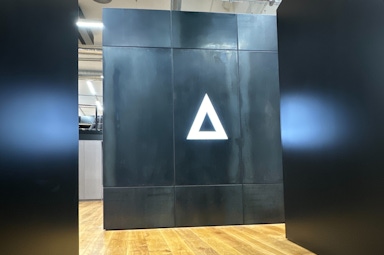

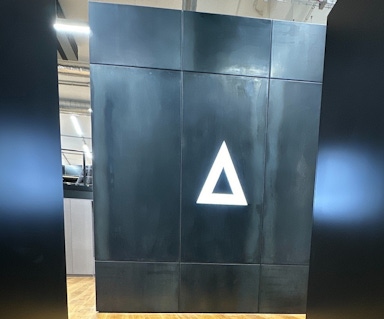

Blackened Steel Cladding

Material Depth and Spatial Elegance

Key Benefits

Distinctive blackened finish with tonal variation

Concealed or expressed fixings for refined detailing

Protective coatings and treatments for longevity

Get in touch with NES today to explore how our cladding solutions can transform your environment