Royal Hospital for Children and Young People, Edinburgh

NES Lightline provided 18 No. Glass face LED Light Boxes on a design, manufacture and installation basis.This exciting project was for the new build home of the RHSC Department of Clinical Neuroscience, Edinburgh.

Each of these units feature a total depth of 71mm. The fixing system is spit aluminium "Z" baton. This is housed within the depth of the unit, meaning the units fit snuggly to the wall with no shadow gap. In addition to this, the fixings are only visible on the two short return edges and therefore, unseen from the available viewing angles. The unit heights are 2,190mm. The face of the units are 7.4mm low iron toughened glass with graphic interlayer.

This is part of the "Beyond Walls" art and therapeutic Design (ATD) programme for the new Royal Hospital for Children and Young People.

Beyond Walls consists of over twenty projects with a team of over thirty artists, designers and makers, forming one of the largest art in healthcare programmes in the UK. This £5m programme has been generously funded by Edinburgh Children’s Hospital Charity and Edinburgh Lothian Health Foundation.

There is a growing recognition of the value of an enriched environment helping to reduce stress and anxiety and this is placed at the heart of the programme. The emphasis is on the integration and enhancement of the patient experience within arrival, waiting, treatment and ward spaces with projects focused on way marking, providing dignity and distraction.

Lead contractor: Ginkgo Projects Ltd

Architect: KSLD Architects

Scope: Design, manufacture and install

Product: LED Light Frame

Location: DCN Reception

Downloads

Ely Museum

Winner of the 2022 RIBA East award, and the 2022 RIBA Conservation Award for East Anglia!Link

NESA was pleased to be part of this renovation and extension of Ely Museum, transforming the Grade 2 listed former Gaol and its surroundings. The project that re-opened to the public in 2021, increased the floor area available for displays, created a new multi-purpose space for education and community programmes, and restored historic features previously hidden from view.

Hat Projects who are also based in Colchester, worked closely with NESA from the beginning. The design was on a tight budget to enable an ambitious 3D design to be realised. This directly complimented the feature of anodised aluminium to appear different colours depending on the angle of incidence.

NESA even anodised the curtain walling for the glazing supplier to match

Go and have a look for yourself at www.elymuseum.org.uk! The nearby cathedral is also a gothic master piece.

Copper Anodised Aluminium in AnoCopper03 Matt etch finish.

40 year warranty, 80 year expected lifetime.

Project details:

Lead contractor: Carter Builders

Architect: Hat Projects

Scope: Survey, design and supply of cladding panels

Downloads

The Rolling Stones Store

Universal Music Group worked with Clements Retail and NES to produce this unique visual merchandising window display.In powder coated red 5mm aluminium the phonic display of the song "Paint it Black" is displayed.

NES assisted with some clever design to fix the aluminium securely with an internal polished stainless steel tube, woven stainless steel cable system.

Wall bracket are also conceiled within the tube. This prevents the display from rotating or swinging into the glass window.

Lensed LED lighting from above highlights the special high gloss Rolling Stones red.

Every one was happy with the finished result, the display seems to float. The fins are all parrallel and show no visible deflection. NES provided all of the product and specifications on this job. This has been achieved in a cost effective, strong and descrete way.

Downloads

Blackened Stainless Steel

NES fabricate and finish blackened stainless steel rain-screen cladding panels and facades.

External Grade:

• NES offer hot blackening of grade 316 stainless steel for external usage. You can specify how consistent and dark you wish this finish to be.

• There will be some change in the blackening over the years as the FeO3 black oxide washes off, fades and mellows. Jet black is not possible or (for me) considered desirable.

• To create this finish, the Chromium needs to be stripped from the face of the stainless steel so the iron can be oxidised in the patina baths. In the presence of free air this Chromium layer then reforms quickly.

• We can leave the sheet mill, radial brushed or linear brushed.

• I have included a couple of interesting projects in New York that have used this exciting finish in the gallery shown above.

The blackened stainless steel cladding panels are available in several finishes:

• Our "patina finish" is designed to exacerbate the organic texture within the surface of the alloy. There is considerably more variance within the colour and texture of the sheet. This is often a source of considerable benefit when viewed on the scale of a facade. To control these extremes NES can provide top and bottom limits for the colour and texture. These can vary over time as the oxide on the facade settles and is impacted by other environmental factors. Fundamentally, stainless steel will continue to be an extremely resilient and long-life product.

• Our "charcoal finish" has been mechanically sanded to harmoginise the colours. Generally, this darkens the panels and makes them a more consistent black. Over time with external exposure, there will still be changes to the colour of the facade. Having a more severe may heighten the visual impact and contrast with the architecture.

NES offer a comprehensive range of fixing systems for the blackened steel cladding panels:

• Our "invisible fix" system makes the panel appear as a 3-dimensional floating block. This can be cantilevered away from the building by up to 500mm to create unique architectural features. We do this by using capacitor discharge studs to weld ribs inside the panels. Please see an excellent example here: Projecting cladding at 257 City Road.

• Our " through face fix" system is more economical and uses much less raw material and fabrication to clad the building. Countersinking of the fixings is available to minimise shadows and rainwater "teardrops" around the fixings. This can be a way of building-in some value engineering into the specification of the blackened steel facade.

Downloads

Blackened Mild Steel

NES Fabricate and finish blacked steel cladding panels. Both hot-rolled mild steel and cold-rolled steel are available.

For Internal Applications only:

• Cold rolled mild steel is grey. We offer a blackened version of this. Cold-rolled steel is hot rolled steel that has been reheated, rolled, and pickled in acid to remove the mill scale and then oiled to reduce rust in transit and storage. The oil gives a slight blue tint in some lights. You tend to get interesting colours from the mix of the elements in the alloy. The way the oil sits on the surface also creates unique coloration effects. The steel is porous absorbing different amounts of oil depending on temperature and the mix of the alloy. You can even get some sheets that have rust pockets on. It is also smoother and flatter due to the secondary processing that brings in some of the tolerances. During the processing there is a degreasing process however, this only takes off the oils that are on the very surface. The max thickness of cold rolled steel is typically 3mm.

• Hot rolled steel is also grey. The cooling process causes a hard mill scale to form on the surface of the metal. This is highly unique to the panels. This surface is rough with a lot of texture. The thickness of hot rolled steel is greater typically 2mm 30mm.

• Finishing:

• NES offers a clear beeswax top coat of this as standard. This just stops fingerprints.

• We can apply a more robust solvent lacquer for high-traffic areas. This has a class 0 surface spread of flame certificate from Warrington Exova . The thickness of the solvent lacquer can detract slightly from the surface quality (it looks a little glossy due to the layer thickness of ~100 microns). The ability of this surface to absorb quite large scratches is impressive.

• We can also offer a clear mat nano lacquer. This is a ~ 5 micron layer and therefore, almost invisible.

How do we install blackend steel wall panels?

NES provides a range of standard and customised fixing systems to suit your requirements:

• "Through face fixing" is an economical choice. We have a countersinking tool for our CNC punch. This allows the fixings to be flush to the surface of the steel and therefore, far less visually intrusive. The fixings can also be blackened to match. In some instances, making a feature of these fixings with pig nose of low profile hex head screws can be a positive element of the finished product.

• "Invisible fix" with a hook-on system is our premium solution. We spot weld 10mm thick split aluminium "Z" baton to the reverse of the sheet on approximately 600mm vertical centres. This allows for the unit to be quickly and seamlessly installed, adjusted, and removed. Generally, we would have 15mm folded return to all edges. This allows the split baton to remain hidden when the sheet is viewed from the edge. Additionally, the folds provide more rigidity for the larger panels.

• "Bonding" can be considered for the thinnest of panels that are going onto a well-prepared surface. Due to considerable negative experiences in the past with differential expansion of metal compared to other materials, we do not recommend this solution. However, with the correct diligence and preparation, it can be a way of achieving a more cost-effective invisible fix.

Downloads

Ribble Cycles

Ribble Cycles wanted a big splash for their flagship Lancashire store.

The goal was to create a holistic sensory experience.

David Stacey, Commercial Director says:

“We wanted to create a brand showcase which would define the future of cycle retailing and represent our world-class credentials. From the moment you step into the showroom you enter a truly immersive experience, and it will completely challenge the notion of a traditional bike shop."

NES Lightline worked closely with Stamp Design to provide our proprietary "LightFrame" extruded aluminium units on a supply and fit basis with some powerful electronics.

Technical Details:

12 No. 2.1 x 0.6m Acrylic faced LED Light Boxes.

This featured the NEW extruded aluminium “Lightframe”. Within these units Matrix LED Panels have been packed with RGBW LEDs. Each of the units is individually addressable via a wireless DMX system. The glass wall mounted plate has 6 settings. These allow the team in the shop to amend the brightness and colours with intuitive control. Behind this user friendly interface there are sophisticated pre-programmed “scenes” with dynamic colour changing across the 12 units. These can be switched or updated, to future proof the display. It would even be possible to plug the DMX controller into a real time emulator of the large digital screen content.

The units were fitted to threaded rod from the ceiling above. Each of these was sleeved with black “HIPS” tube.

Ribble Cycles wanted their showroom to provide a truly immersive experience. The LED "Lightframe" with RGBW LEDs were provided, giving complete DMX control for this amazing Clitheroe store. The units are controlled wirelessly, all linked to 'touch' control.

Downloads

Exeter Road

Working closely with the architect Selencky Parsons NESA provided a bespoke manufactured feature cladding for the new dance studio at Exeter Road, North London.The new building is situated within the Mapesbury Conservaiton Area, demanding design innovation and sensitivity to the local envoronment. The existing house has an extension on the back that is accented with the same anodised colour "AnoBrass02" on the curtain walling and planter as the dance studio. The new building and extended house is now home to post graduate students who live and perform on site.

The bespoke design detailing allowed for both invisible fix system and installation tollenance. Such a complex 3D structure demanded not only full modeling and a "dry assembly" of the arch modules before attending site for final installation.

"It is an exceptional design that has been greatly admired and is certainly being put to good use ... it was refreshing to have your company on site. Not only were your operatives highly skilled, but the whole operation was well organised and efficiently executed. I would have no hesitation in recommending your Company."

Richard M Jenkins

Founder Trustee, The Amar-Franses & Foster-Jenkins Trust

Project details:

Architect: Selencky Parsons Architects

Client: Amar-Frances Foster-Jenkins Trust

Scope: Design manufacture and installation

Material: Anodised aluminium cladding "AnoBrass03"

Scale: 120 sq. m

Photo credits: Richard Chivers

Downloads

Southmere Library

Southmere Civic & Library Building.Description: This project was taken on as a turnkey design, manufacture and installation service. The sub structure for the rails was insulated panels by others. The fixing system used was the "NES Secret Fix System - PPSF02". There was the concern that the maintenance of the LEDs would be a challenge with such large panels in front of them. To solve this NESA designed bespoke locking brackets that allow the panels to be removed 300mm from the wall while still mechanically fixed to the rails.

The LEDs feature elliptical lenses 5 x 50 degrees. They are mounted in vertical lines with louvres to stop the light bleed through the holes from blinding people. The light bounces off the supporting panel and then is visible through the holes.

"NES did an excellent job on the Southmere Library project, they developed the RIBA competition winning concept design into a detailed back lit cladding solution, produced a full scale sample / demo in their factory for us to visit and the finished product is fantastic and truly delivers on the brief provided for this landmark building."

Kind Regards

Russell Murphy FCIOB CEnv BSc (Hons)

Construction Director

Durkan

Scope: 550 sq. m of aluminium cladding. Perforated and back lit.

Client team: Bisset Adams architects

Lead Contractor: Durkan.

Downloads

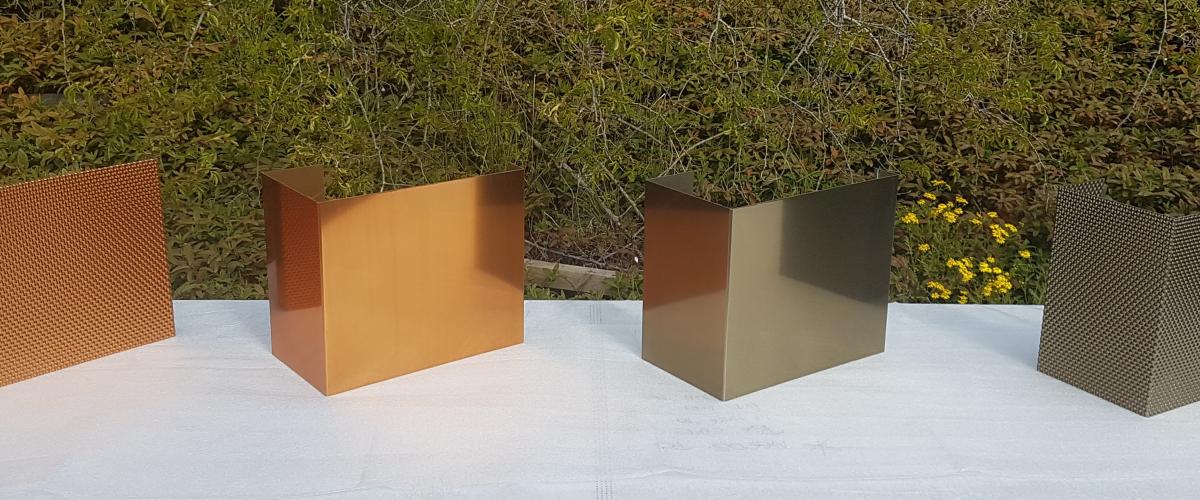

New anodised finishes from NESA

New anodised finishes from NESA

Under the brand "AnoAli" NES Architectural has expanded the structured surfaces available.

These now include bright finish and embossed finish panels.

The bright finish brings a high level of reflectivity to the panels. The embossing has also been polished, catching the light while protecting the surface. Different embossing effect are possible.

The brushed and matt finishes are also available.

At the end of Q2 NESA will be providing a "Vibration" finish for an exciting project on the Isle of Skye!